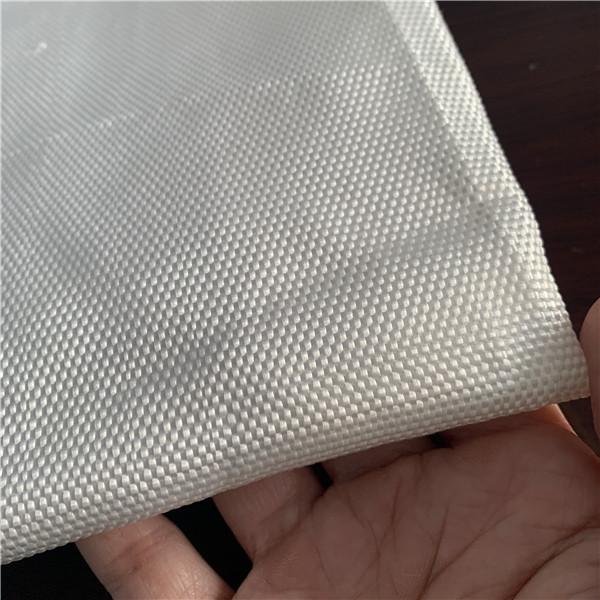

Woven Geotextile For Construction

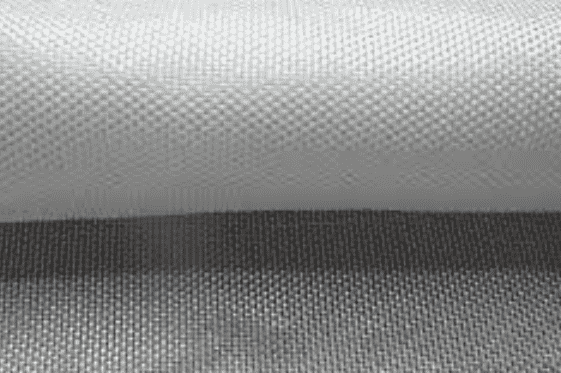

Woven Geotextile For Construction-Woven geotextiles are made of high-strength industrial artificial fibers and produced via weaving technology.

Features: High strength: High-strength industrial polypropylene, polyester, nylon and different artificial fibers are used as uncooked materials, with excessive unique strength. After weaving, it varieties a ordinary interweaving structure, and the complete bearing capability is similarly improved.

Durability: The attribute of artificial chemical fiber is that it is now not handy to denature, decompose and weather. It can keep its unique traits for a lengthy time.

Corrosion resistance: Synthetic chemical fibers commonly have acid resistance, alkali resistance, insect resistance, and mould resistance.

Water permeability: Woven fabric can correctly manipulate their structural pores to reap a positive diploma of water permeability.

Convenient storage and transportation: due to mild weight and can be packed in accordance to sure requirements, it is very handy for transportation, storage and construction.

Woven Geotextile For Construction

Product Description:

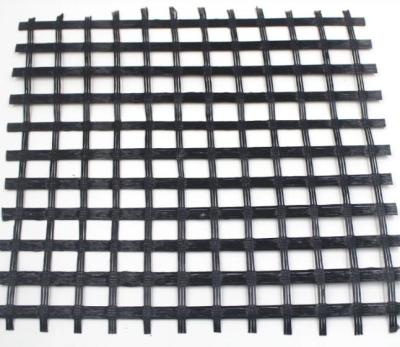

Advanced woven geotextiles take gain of the industrialization and low value of artificial fibers; PP/PE is used as the fundamental uncooked cloth and produced with the aid of weaving process. Light weight, excessive strength, low elongation, durability, corrosion resistance, accurate integrity, etc. Features: The traits of the hermetic braided fabric shape and the non-compliant rate of engineering parameters meet the fluctuation necessities of one of many elements such as filtration, isolation, reinforcement, and safety in geotechnical engineering. It is a incredible reasonably priced product in geotechnical engineering. Under construction.

In order to make the balance and steadiness of the product form and the compliance price of the engineering parameters, our company's filament woven geotextiles are all produced by means of wide-width shuttleless looms to gain first-rate quality.

Woven Geotextile For Construction Application:

High strength: Polypropylene, polyester, nylon and different artificial fibers are used as uncooked materials, which have excessive unique strength. After weaving, they shape a normal interweaving structure, and the complete bearing capability is in addition improved.

Durability: The attribute of man-made chemical fiber is that it is no longer effortlessly denatured, decomposed, and weathered. It can keep its special traits for a lengthy time.

Corrosion resistance: Synthetic chemical fibers normally have houses such as acid resistance, alkali resistance, insect resistance, and mildew resistance.

Water permeability: woven fabric can efficaciously manage their structural pores to acquire a positive diploma of water permeability

Convenient storage and transportation: due to mild weight, it can be packaged in accordance to the the front requirements, and transportation, storage and building are very handy.

Woven Geotextile For Construction Features:

High strength: Polypropylene, polyester, nylon and different artificial fibers are used as uncooked materials, which have excessive authentic strength. After weaving, they structure a everyday interweaving structure, and the complete bearing potential is in addition improved.

Durability: The attribute of man-made chemical fiber is that it is no longer without difficulty denatured, decomposed, and weathered. It can preserve its special traits for a lengthy time.

Corrosion resistance: Synthetic chemical fibers normally have homes such as acid resistance, alkali resistance, insect resistance, and mildew resistance.

Water permeability: woven fabric can correctly manage their structural pores to obtain a sure degree of water permeability

Convenient storage and transportation: due to mild weight, it can be packaged in accordance to the the front requirements, and transportation, storage and development are very handy.

High Quality Woven Geotextile technical standards:

Product Series | Unit | Allowable Deviation | Woven Geotextile | ||||

ZXF-180 | ZXF-230 | ZXF-260 | ZXF-340 | ZXF-670 | |||

Mass per unit area (single) | G/㎡ | -3% | 180 | 230 | 260 | 340 | 670 |

Tensile strength (longitudinal) | N/5cm | ≥ | 2300 | 2900 | 3300 | 4300 | 10000 |

Elongation (longitudinal) | % | ≤ | 30 | 30 | 30 | 30 | 30 |

Tensile strength (transverse) | N/5cm | ≥ | 1800 | 2350 | 2600 | 3100 | 6000 |

Elongation (transverse) | % | ≤ | 25 | 25 | 27 | 25 | 25 |

Trapezoidal tear strength (longitudinal) | N | ≥ | 850 | 1175 | 1300 | 1500 | 3000 |

Trapezoidal tear strength (transverse) | N | ≥ | 540 | 1107 | 1250 | 1400 | 2800 |

Breaking strength of CBR | N | ≥ | 4700 | 6500 | 7200 | 8000 | 19000 |

Vertical permeability coefficient | Cm/s | ≥ | 2.5*10^ (-3) | 2.3*10^ (-3) | 3* 10^ (-3) | 8*10^ (-3) | 1*10^ (-3) |

Equivalent aperture O95 | mm | ≤ | 0.042 | 0.053 | 0.1 | 0.12 | 0.45 |

Packing of Woven Geotextile For Construction

You can freely choose PE film or PP woven bag for outer packaging, and there are paper tubes of different sizes inside the product for you to choose freely.

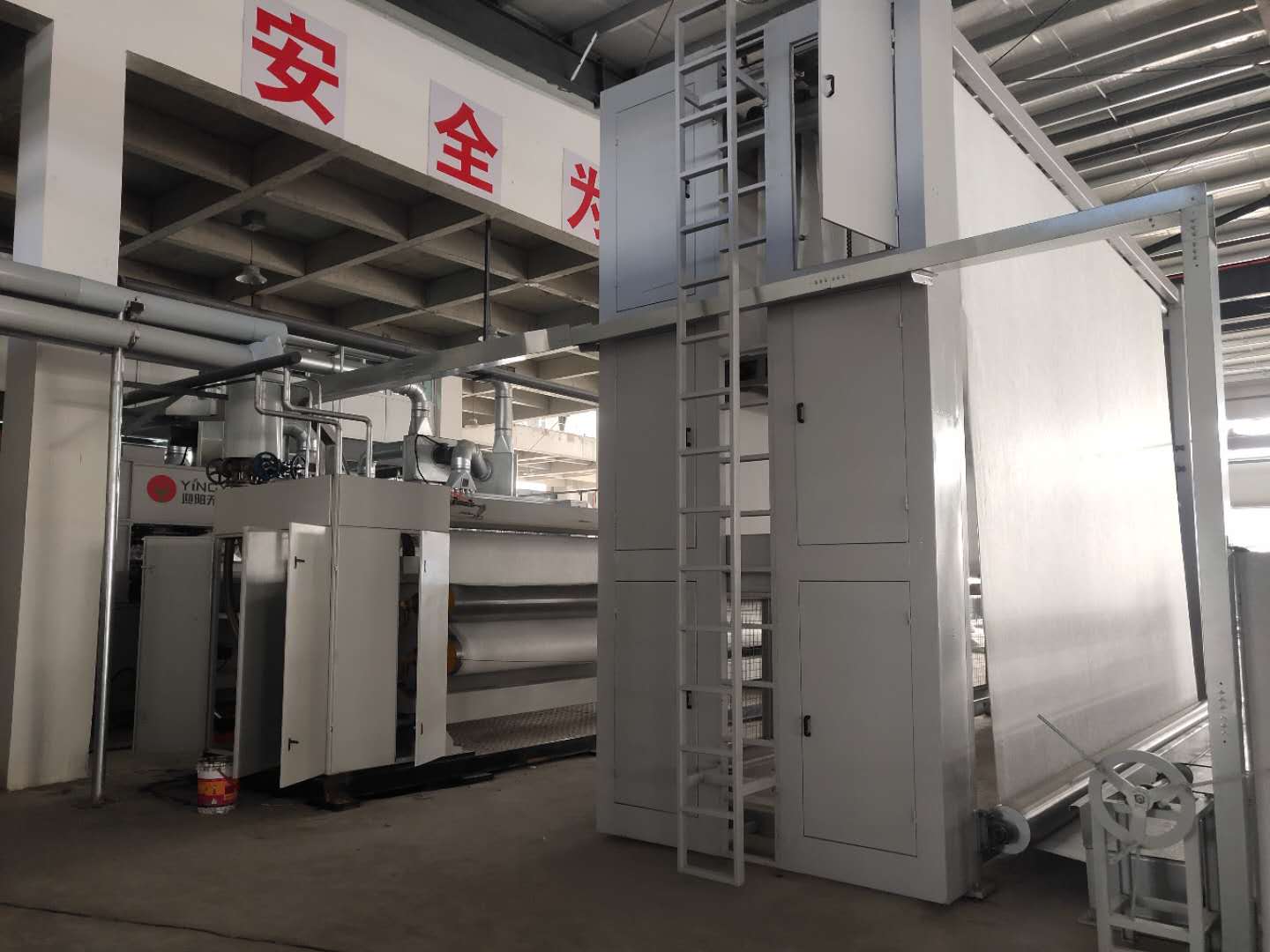

Strength of the company

With first-rate mechanical equipment, senior technical personnel and a big manufacturing team, the annual output of geotextiles is extra than 30 million rectangular meters, and it has been diagnosed as a magnificent cloth dealer by means of the country wide authority. It sells nicely in Southeast Asia and some European areas in South America. It affords terrific and dependable merchandise and provider ensures for building corporations