The combination of geotextile and geomembrane plays a key role in anti-seepage and reinforcement projects.

The matching technology of non-woven geotextiles and geomembranes (referred to as "cloth-membrane combination") has shown significant advantages in landfills, water

conservancy projects, mine restoration and other fields. Recently, the China Geomaterials Association and a number of scientific research institutions released the "Technical

Guidelines for the Supporting Application of Geosynthetic Materials", emphasizing the importance of collaborative design of non-woven geotextiles and geomembranes,

providing a scientific reference for the industry.

---

**1. Non-woven geotextiles and geomembranes: complementary functions and doubled effectiveness**

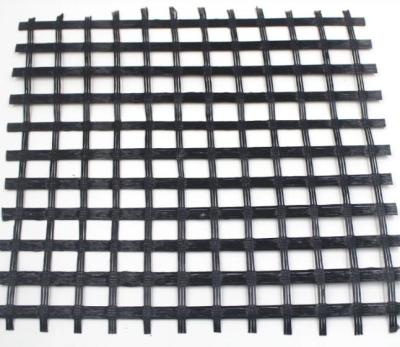

Non-woven geotextiles are often used as the "protective layer" and "drainage layer" of geomembranes due to their high water permeability, puncture resistance and flexibility.

Geomembrane (such as HDPE membrane) can effectively block the migration of liquid or gas with its excellent anti-seepage performance. After the two are combined,

a three-in-one composite structure of "anti-seepage + protection + drainage" is formed. The specific advantages include:

1. **Extended service life**: Geotextile buffers external loads and sharp object impacts, reducing the risk of mechanical damage to the geomembrane.

2. **Improve anti-seepage stability**: The geotextile promotes interface drainage and prevents the accumulation of water pressure from causing the geomembrane to bulge

and rupture.

3. **Cost reduction**: Reduce the thickness requirement when using geomembrane alone and optimize material costs.

---

**2. Typical application scenarios and technical points**

1. **Landfill**

- **Structural Design**: From top to bottom are non-woven geotextile (above 600g/m²), HDPE geomembrane (above 1.5mm), and compacted clay layer.

- **Function**: The geotextile protects the membrane material from damage by garbage debris and at the same time leads the leachate to the collection system.

2. **Artificial Lakes and Reservoirs**

- **Construction Specifications**: After the geomembrane is laid, cover it with 300g/m² non-woven geotextile and backfill the soil layer to avoid ultraviolet aging and plant root

penetration.

3. **Mine tailings pond**

- **Innovative solution**: Adopt a "double cloth sandwiched membrane" structure (geotextile-geomembrane-geotextile) to enhance chemical corrosion resistance. ---

**3. Key construction technologies and industry initiatives**

The China Geotechnical Materials Association pointed out that "fabric-membrane bonding" needs to follow the following specifications:

- **Overlapping treatment**: The geotextile is stitched or overlapped (overlapping more than 30cm), and the geomembrane needs to be hot-melt welded and tested for air tightness.

- **Slope adaptation**: In steep slope areas, rough geomembranes should be used and anchor trenches should be added to enhance friction with geotextiles.

- **Quality Inspection**: Use an electric spark detector to check for leaks in the geomembrane to ensure there is no leakage hazard.

---

**4. Case sharing: Successful practice proves the value of technology**

In 2025, in the Australian coastal ecological restoration project, a combination of "high-strength non-woven fabric + composite geomembrane" was used to successfully resist

flood erosion, with an anti-seepage efficiency of 99.9% and a 15% reduction in project costs.

---

**5. Industry Outlook**

"The collaborative application of geotextiles and geomembranes is an inevitable trend in the development of geotechnical engineering in the future." Li Guoqiang, a professor

at the Department of Water Conservancy at Tsinghua University in China, said, "With the upgrade of material performance and the introduction of intelligent construction

technology, the 'textile-membrane combination' will play a greater role in carbon neutrality, sponge cities and other fields."

---

**About Us**

Shandong Taiwei Engineering Materials Co., Ltd. is committed to promoting technological innovation and standardized application of geosynthetic materials, and providing technical training, project docking and policy guidance services to the global geotechnical engineering field.