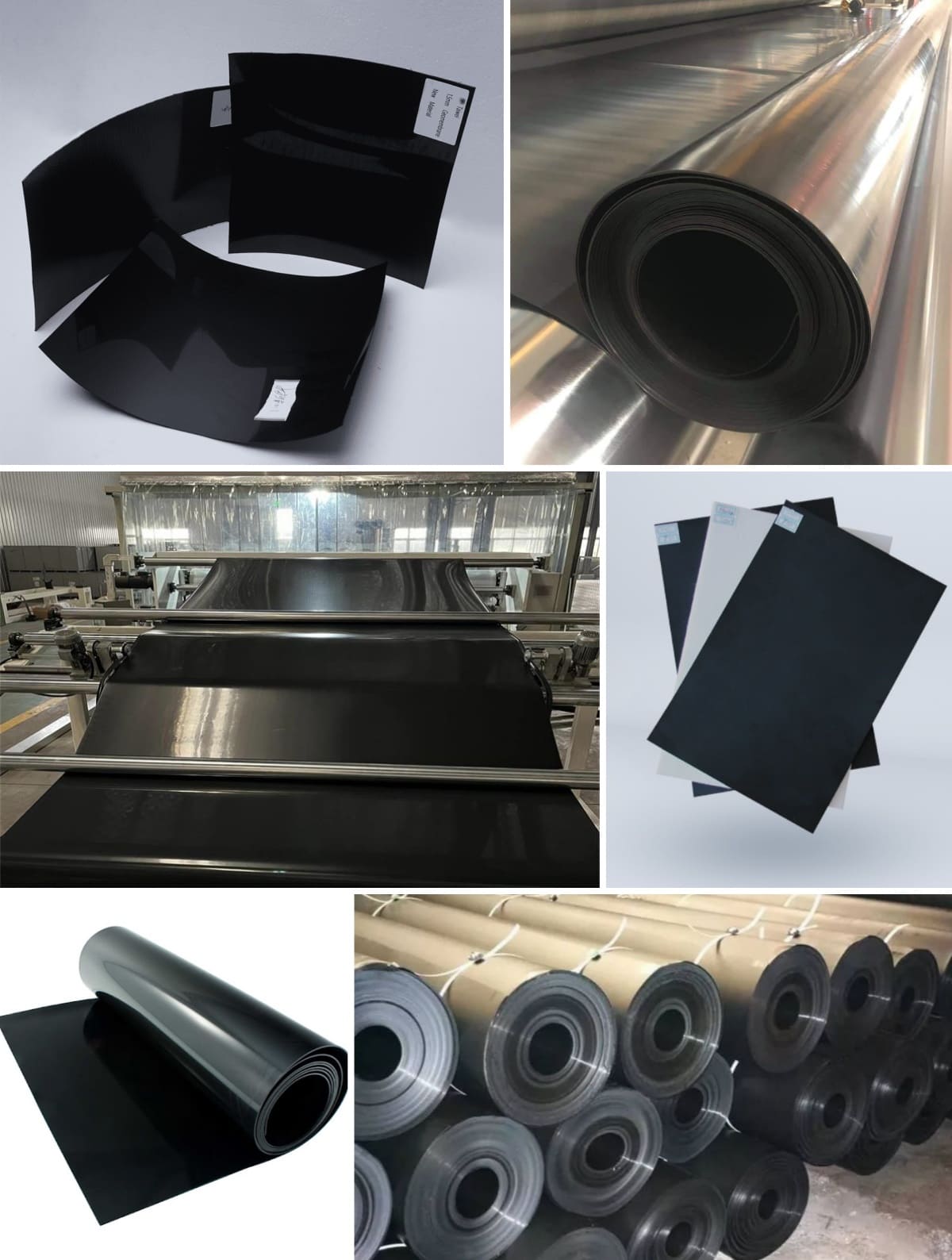

Chemical anti-seepage geomembrane

HDPE geomembrane is produced through either a three-layer co-extrusion method or a calendering technique. This material acts as an outstanding barrier to water, rendering it highly beneficial for various engineering applications.

1. Excellent resistance to penetration, offering waterproofing, anti-seepage, and isolation properties.

2. Remarkable resistance to chemical degradation.

3. Improved impact resistance and longevity against wear.

Product descriptions from the supplier

: HDPE geomembrane

:

:

:

:

: 1m-8m(Customizable)

: 50m-200m/Roll (Customizable)

:

:

: ISO9001/ISO14001/ISO45001/CE-CCSD23010543609/CRCC

: Within 10 years (Based on actual product conditions)

: Online technical support, installation training, on-site guidance.

Product features

1. The HDPE geomembrane showcases outstanding chemical stability, exhibiting resistance to strong acids, alkalis, and oil degradation. It functions as a durable anti-corrosion material.

2. The HDPE geomembrane is characterized by its remarkable tensile strength, making it ideal for a variety of high-quality projects.

3. The HDPE geomembrane demonstrates significant resistance to local weather conditions and possesses excellent anti-aging properties, ensuring extended usability without a reduction in effectiveness.

4. The HDPE geomembrane delivers reliable performance throughout its operational life. It boasts strong tensile strength and elongation at break, making it suitable for use in demanding geological and climatic conditions. It is capable of adapting to uneven geological landscapes and shows resilience to stress.

Product Application

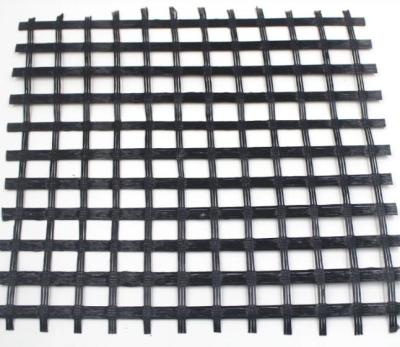

1. Water management strategies: utilized for anti-seepage lining in reservoirs, channels, dams, rivers, and similar infrastructures.

2. Environmental protection: employed for anti-seepage barriers in vital locations such as landfills, sewage treatment plants, and chemical production facilities to prevent the infiltration of hazardous materials into groundwater or soil, thereby effectively reducing soil erosion and leakage.

3. Agriculture and aquaculture: used for anti-seepage barriers in environments like pools, fish ponds, and aquaculture ventures, which can significantly minimize water resource loss and improve breeding efficiency.

4. Infrastructure: applied for anti-seepage barriers in roads, railways, airports, and various foundational projects, enhancing both aesthetic appeal and structural integrity.

Product indicators

| HDPE Geomembrane Technical Parameter (GRI GM13 ASTM Standard) | ||||||||||

| Spec Properties | Test method ASTM | GMS0.2 | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 | GMS3.0 |

| Thickness | D5199 | 0.2mm | 0.5mm | 0.75mm | 1.00mm | 1 .25mm | 1.50mm | 2.00mm | 2.50mm | 3.00mm |

| Density (≥ g/cc) | D1505 | 0.94 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.94 |

| Tensile Properties (Each direction)(≥) • yield strength • break strength • yield elongation • break elongation | D6693 Type IV | 3 kN/m 5 kN/m 12% 700% | 8 kN/m 14 kN/m 12% 700% | 11 kN/m 20 kN/m 12% 700% | 15 kN/m 27 kN/m 12% 700% | 18 kN/m 33 kN/m 12% 700% | 22 kN/m 40 kN/m 12% 700% | 29kN/m 53 KN/m 12% 700% | 37kN/m 67kN/m 12% 700% | 44kN/m 80kN/m 12% 700% |

| Tear Resistance (≥) | D 1004 | 25N | 64N | 93N | 125 N | 156N | 187N | 249 N | 311 N | 374 N |

| Puncture Resistance(≥) | D 4833 | 64N | 160N | 240N | 320 N | 400 N | 480N | 640 N | 800 N | 960 N |

| Stress Crack Resistance (≥) | D 5397 | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr | 500 hr |

| Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

| Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

| Oxidative Induction Time(OIT)(≥) (a)Standard OIT ——or—— (b)High Pressure OIT | D 3895 D 5885 | 100min 500min | 100 min 500 min | 100 min 500 min | 100 min 500 min | 100 min 500 min | 100 min 500 min | 100 min 500 min | 100 min 500 min | 100 min 500 min |

Packaging and Transportation

Company Introduction

FAQ

Can you design for us?

We have a professional design team to help our clients with their design work.

Do you accept processing orders?

We provide OEM and ODM services to customers.

Can we get the sample from your factory?

We can provide you with samples for free, but you need to pay the express fee before the first cooperation.

Can you have our brand printed on your products?

Yes. If you can meet our MOQ, we can print your logo on the product and packaging.

How do you guarantee the quality of the product for us?

We have a professional quality control team, and each product is strictly inspected before shipment.

How long is your delivery time?

Small orders take about one week, large orders need to be negotiated based on factory orders.

What is your method of payment?

We accept T/T, L/C, Western Union or negotiation. Don't worry about anything, if you have any questions please feel free to contact us.